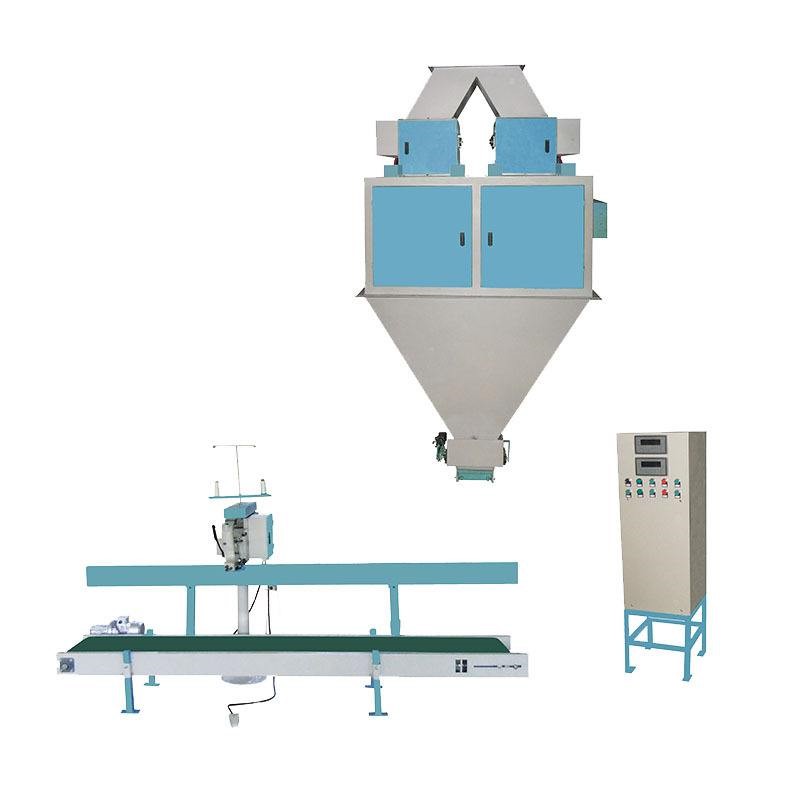

DCS50-C2 (Ihe na-ejuputa: Granule, Hopper abụọ na-atụ aro)

DCS50-C2 (Ihe na-ejuputa: Granule, Hopper abụọ na-atụ aro)

Okwu mmalite

DCS50-C2 bụ tumadi mejupụtara Gravity filler / Auger filler, etiti, n'elu ikpo okwu na-atụ, nghọta akpa ngwaọrụ, clamping ngwaọrụ, ebuli elu ikpo okwu, ebu, eletriki akara usoro, pneumatic akara usoro, wdg Mgbe nkwakọ usoro na-arụ ọrụ, na mgbakwunye na nke jiri aka tinye akpa n'ime ọnọdụ, usoro nkwakọ ngwaahịa ọzọ na-emecha na-akpaghị aka site na njikwa mmemme PLC, na usoro nke ịkwakọba akpa, oghere, metering, akpa rụrụ arụ, mbufe, wdg ga-arụ ọrụ n'aka;Usoro nkwakọ ngwaahịa nwere njirimara nke ọnụ ọgụgụ ziri ezi, ịrụ ọrụ dị mfe, obere mkpọtụ, obere uzuzu, nhazi kọmpat, ntinye dị mfe, nchekwa na ntụkwasị obi, na ntinye nchekwa n'etiti ụlọ ọrụ.

Njirimara

| Njirimara | ||

| Filler | Ihe ndochi ike ndọda / Auger filler | |

| Gụọ | Ọnụ ụgbụ ụgbụ abụọ | |

| Usoro njikwa | Arụ ọrụ dị ka mgbazi dobe akpaka, mkpu njehie na nchọpụta onwe onye kpatara, Ejiri ya na nzikọrịta ozi, dị mfe ijikọ, netwọkụ, a na-enyocha usoro nkwakọ ngwaahịa oge niile yana njikwa netwọkụ. | |

| Oke ihe: ntụ ntụ, granular ihe. | ||

| Oke ngwa: Chemical, ọgwụ, ndepụta, fatịlaịza, ịnweta ntụ ntụ, eletriki ike, coal, metallurgy, ciment, ndu engineering, wdg | ||

| Paramete | ||

| Ike | 300-700bag / h | |

| izi ezi | ≤±0.2% | |

| Nha | 6-60kg/akpa | |

| Isi iyi ike | ahaziri | |

| Ikuku nrụgide | 0.6-0.8MPa, 5-10 m3 / h | |

| Oke na-afụ | 600-2200m3 / h | |

| Gburugburu: Okpomọkụ -10 ℃-50 ℃, iru mmiri | 80% | ||

| Ngwa ngwa | ||

| Ebe akpa | 1, Iji aka 3, Na-akpaghị aka | |

| Nchedo | 1, Ihe mgbawa 2, Enweghị ihe mgbawa | |

| Mkpochapụ uzuzu | 1, mkpochapụ uzuzu 2, Ọ dịghị | |

| Ihe onwunwe | 1, Steel 2, igwe anaghị agba nchara | |

| Palletizzing | Palletizzing akwụkwọ ntuziaka, Palletizzing dị elu, Robot Palletizzing | |

| ịkwa akwa | Akpaaka 2.Manual | |

Isi ihe na ọrụ

1 Usoro ndochi: ezi izi ezi nke njikwa ndochi ihe ma mechie njuputa na-akpaghị aka;na-achịkwa izi ezi nke ndochi ihe site na ntụgharị ntụgharị nke efere valve, ya bụ, nha nke akụkụ mmiri na-asọpụta, ma mechie valvụ na-ejuputa mgbe ịdị arọ dị mma.

2 Ikpokoro ibu ibu: Ejiri ya na Toledo bellows load cell, nke a na-eji tụọ ihe dị arọ ma tinye ihe ahụ n'ime akpa nkwakọ ngwaahịa.

3 Platform bracket: eji akwado akụrụngwa ma dị mfe idobe akụrụngwa.

4 Igbe nchịkwa eletrọnịkị: iyuzucha nke etiti, igbe ahụ mechiri, cylinder na njikwa valvụ solenoid.

5 Sistemụ nha bụ nha nha eletrọnịkị, ngwa ngosipụta njikwa nha bụ ngosipụta dijitalụ, yana nrụzi dijitalụ zuru oke na ntọala paramita na-eme ka usoro ọrụ dị mfe.Ndozi, mkpu na-enweghị nnabata na mmejọ nchọpụta onwe na ọrụ ndị ọzọ.Ngwá ọrụ ahụ nwere ngwa nzikọrịta ozi, nke dị mma maka ịntanetị na ịkparịta ụka n'Ịntanet, ma nwee ike nyochaa ma jikwaa igwe nkwakọ ngwaahịa n'ọfịs.