DCS50-L Automatic filling machine

DCS50-L Automatic filling machine

Introduction

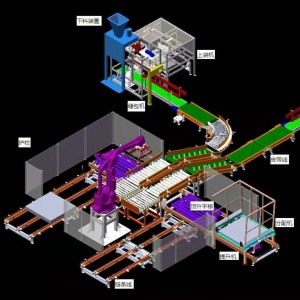

DCS50-L is mainly composed of auger filler (frequency conversion speed regulation), frame, weighing platform, hanging bag device, bag clamping device, lifting platform, conveyor, electrical control system, pneumatic control system, etc. When the packaging system works, in addition to the manually place bag, the packaging process is automatically completed by the PLC program control, and the procedures of bag clamping, blanking, metering, loose bag, conveying, etc. are completed in turn; The packaging system has the characteristics of accurate counting, simple operation, low noise, less dust, compact structure, convenient installation, safety and reliability, and safe interlocking between the workstations.

Characteristics

| Characteristics | ||

| Filler | Auger filler | |

| Count | Counting as hanging | |

| Control system | Functions such as automatic drop correction, error alarm and fault self-diagnosis,Equipped with a communication interface, easy to connect, network, can be the packaging process at all times monitored and networked management. | |

| Scope of material:Powders, granular materials. | ||

| Scope of application:Chemical, pharmaceutical, feed, fertilizer, mineral powder, electric power, coal, metallurgy, cement, biological engineering, etc | ||

| Paramete | ||

| Capacity | 200-300bag/h | |

| Accuracy | ≤±0.2% | |

| Size | 5-50Kg/bag | |

| Power souce | Customized | |

| Pressure air | 0.6-0.8MPa. 5-10 m3/h | |

| Blowing rat | 500 -2000m3/h | |

| Environment:Temp -10℃-50℃. Humidity<80% | ||

| Accessories | ||

| Place bag | 1. Manual 3. Automaitic | |

| Protection | 1. Explosion-proof 2. No explosion-proof | |

| Dust elimination | 1. Dust elimination 2. No | |

| Material | 1. Steel 2. stainless steel | |

| Palletizzing | Manual Palletizzing, High-low Palletizzing,Robot Palletizzing | |

| Sew |

|

|

Performance characteristics

1.This equipment is mainly used for quantitative filling of powder materials.

2.Screw feeding, frequency conversion speed regulation, packing speed and precision can be adjusted.

3.The weighing and measuring control system is digital display, and the system parameters can be set arbitrarily; the sensor is METTLER TOLEDO brand. Electrical components are Schneider brand.

4.The control components of the pneumatic system are imported products, the executive components are domestic high-quality products, and the air control box is a sealed box placed on the body.

5.The equipment has a dust-proof structure design, and is equipped with a dust-removing interface to connect with the dust-removing equipment, which has a good dust-removing effect.

Work process

Manual bagging---press the start button to clamp the bag---automatic start of fast feeding---automatic conversion to slow feeding when reaching the set value---automatic closing of the stop valve at the end of slow feeding---automatic opening of the bag clamper The packaging bag falls on the conveyor belt - conveying the seam bag - repeating the above cycle. The whole process only needs manual bagging, and other actions are automatically completed by PLC control.